Tandem die is a stamping die that can complete multiple processes at the same time, which solves the problem of low efficiency and high processing cost that the existing stamping die can only process one shape.

With simple structure and reasonable design, the stamped parts not only have good dimensional stability, precise size and no deformation, but also have short production cycle. They are widely used in many fields such as cold rolled steel or zinc aluminum alloy parts, and have broad market value and huge market potential.

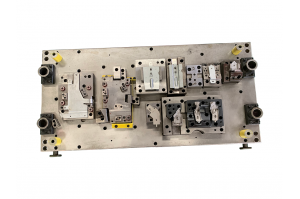

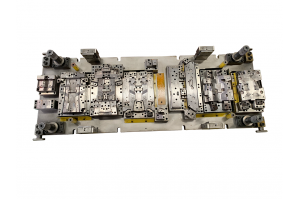

As shown below, these are tandem dies made by Meilin. Four parts or three parts are produced on the same die, with different shapes, materials and material thicknesses.

Because of the simple structure of the die, it can reduce the cost, high efficiency and meet the demand of mass production. It will not occupy the punch and save time.

For the holes of the part, we use laser blank. Laser cutting is widely used in stamping parts, which is easy to control, highly accurate and cost effective. For high tolerance, short lead time, simple shape metal parts, laser cutting machine is a good choice.

For lower volume, urgent automotive stamping metal parts, laser cutting shows simple design, quick production, we could test the product quality in very short time, and proceed to mass production immediately.

Post time: Mar-11-2022